B) False

Correct Answer

verified

True

Correct Answer

verified

True/False

If a point on a control chart falls outside one of the control limits, this suggests that the process output is nonrandom and should be investigated.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

A time-ordered plot of sample statistics is called a(n) _____ chart.

A) statistical

B) inspection

C) control

D) simo

E) limit

G) A) and C)

Correct Answer

verified

Correct Answer

verified

True/False

Attributes need to be measured, whereas variable data can be counted.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Acceptance sampling, when it is used, is used (I) before production.(II) during production.(III) after production.

A) I only

B) I and III only

C) I and II only

D) II and III only

E) I, II, and III

G) B) and E)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

A control chart used to monitor the number of defects per unit is the

A) p-chart.

B) R-chart.

C) x-bar chart.

D) c-chart.

E) Gantt chart.

G) None of the above

Correct Answer

verified

Correct Answer

verified

True/False

Tolerances represent the control limits we use on the charts.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

The purpose of control charts is to

A) estimate the proportion of output that is acceptable.

B) weed out defective items.

C) determine if the output is within tolerances/specifications.

D) distinguish between random variation and assignable variation in the process.

E) provide meaningful work for quality inspectors.

G) B) and D)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Inspection is a(n) _____ activity.

A) prevention.

B) capability analysis.

C) flawless

D) corrective.

E) appraisal.

G) A) and B)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

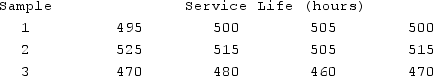

A design engineer wants to construct a sample mean chart for controlling the service life of a halogen headlamp his company produces. He knows from numerous previous samples that this service life is normally distributed with a mean of 500 hours and a standard deviation of 20 hours. On three recent production batches, he tested service life on random samples of four headlamps, with these results

What is the standard deviation of the sampling distribution of sample means for whenever service life is in control?

What is the standard deviation of the sampling distribution of sample means for whenever service life is in control?

A) 5 hours

B) 6.67 hours

C) 10 hours

D) 11.55 hours

E) 20 hours

G) C) and E)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

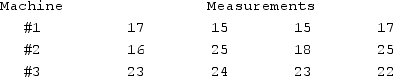

A quality analyst wants to construct a control chart for determining whether three machines, all producing the same product, are in control with regard to a particular quality variable. Accordingly, he sampled four units of output from each machine, with the following results

What is the sample mean for machine #1?

What is the sample mean for machine #1?

A) 15

B) 16

C) 17

D) 21

E) 23

G) A) and D)

Correct Answer

verified

Correct Answer

verified

True/False

Control limits are based on multiples of the process standard deviation.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

A process results in a few defects occurring in each unit of output. Long-run, these defects should be monitored with

A) p-charts.

B) c-charts.

C) x-bar charts.

D) R-charts.

E) o-charts.

G) B) and E)

Correct Answer

verified

Correct Answer

verified

True/False

Approving the effort that occurs during the production process is known as acceptance sampling.

B) False

Correct Answer

verified

Correct Answer

verified

True/False

Range charts and p-charts are both used for variable data.

B) False

Correct Answer

verified

False

Correct Answer

verified

Multiple Choice

Statistical process control charts are not really used to fix quality so much as they are used to

A) highlight when processes are not capable.

B) point out when random variation is present.

C) alert when corrective action is needed.

D) monitor the quality of incoming shipments or outgoing finished goods.

E) initiate team-building exercises.

G) All of the above

Correct Answer

verified

Correct Answer

verified

True/False

The purpose of statistical process control is to ensure that historical output is random.

B) False

Correct Answer

verified

Correct Answer

verified

True/False

The traditional view is that the optimum level of inspection occurs when we catch at least 98.6 percent of the defects.

B) False

Correct Answer

verified

Correct Answer

verified

Multiple Choice

Consider the following information

The number of runs above and below the sample median is:

The number of runs above and below the sample median is:

A) 3.

B) 4.

C) 5.

D) 6.

E) none of these.

G) B) and C)

Correct Answer

verified

Correct Answer

verified

Multiple Choice

The specification limits for a product are 8 cm and 10 cm. A process that produces the product has a mean of 9.5 cm and a standard deviation of 0.2 cm. What is the process capability, Cpk?

A) 3.33

B) 1.67

C) 0.83

D) 2.50

E) 1.33

G) A) and D)

Correct Answer

verified

C

Correct Answer

verified

Showing 1 - 20 of 117

Related Exams